I’m certain we will be able to all agree that the worst time to determine a magnet is the mistaken manner round is after glue has been carried out. With that during thoughts, [erick.siders] created the parametric Magnet Placer instrument.

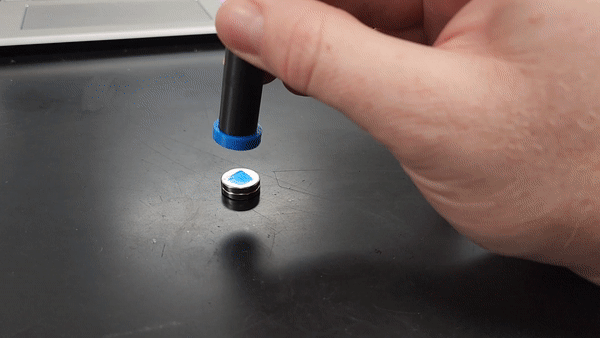

Selecting up and putting magnets into assemblies may also be an error-prone procedure, as a result of magnet polarity can’t be without delay recognized or sensed by means of both sight or fingertips. This instrument is helping by means of performing so much like a suction pickup instrument — press the plunger down, and a magnet may also be picked up, unencumber the plunger, and the magnet we could pass. Easy, and efficient.

Because the instrument is polarity-dependent (relying on which orientation the pickup magnet is fastened into the inner plunger), [erick.siders] suggests printing two equipment and color-coding them. That manner, one can select the appropriate instrument in response to the placement and be assured that the magnets are right-side-up, each time.

The equipment use an extended metric bolt, a magnet, and a spring, however none of the ones portions are in particular essential. We additionally love the best way that the result has no gaps or openings into the transferring portions, because of this not anything can get stuck on or inside of the rest all over use or garage.

It’s a parametric design and the CAD recordsdata (in each Fusion 360 and STEP flavors) are supplied, so amendment must be a breeze. And for those who occur to be the use of PrusaSlicer, take into accout you’ll now drop STEP structure recordsdata without delay in for chopping.