Floor mount elements were a recreation changer for the electronics hobbyist, however doing reflow soldering proper calls for some technique to calmly warmth the board. You may want to purchase a business reflow oven — you’ll be able to cobble one in combination from an outdated toaster oven, finally — however you continue to want one thing, as it’s no longer like a PCB goes to solder itself. Proper?

Unsuitable. A minimum of for those who’re [Carl Bugeja], who got here up with a artful technique to make his PCBs self-soldering. The speculation is to make use of some of the interior layers on a four-layer PCB, which might usually be dedicated to a floor airplane, as a integrated heating part. Somewhat than a vast, steady layer of copper, [Carl] made an extended, twisting hint overlaying all the space of the PCB. Routing the hint round vias was once slightly tough, however after all he controlled a unmarried hint with a resistance of about 3 ohms.

When attached to a bench energy provide, the PCB in fact heats up briefly and lovely calmly judging by way of the IR digital camera. The standard of the soldering turns out similar to what you’d see from a reflow oven. After soldering, the now-useless heating part is transformed right into a floor airplane for the circuit by way of breaking off the terminals and soldering on a few 0 ohm resistors to quick the coil to floor.

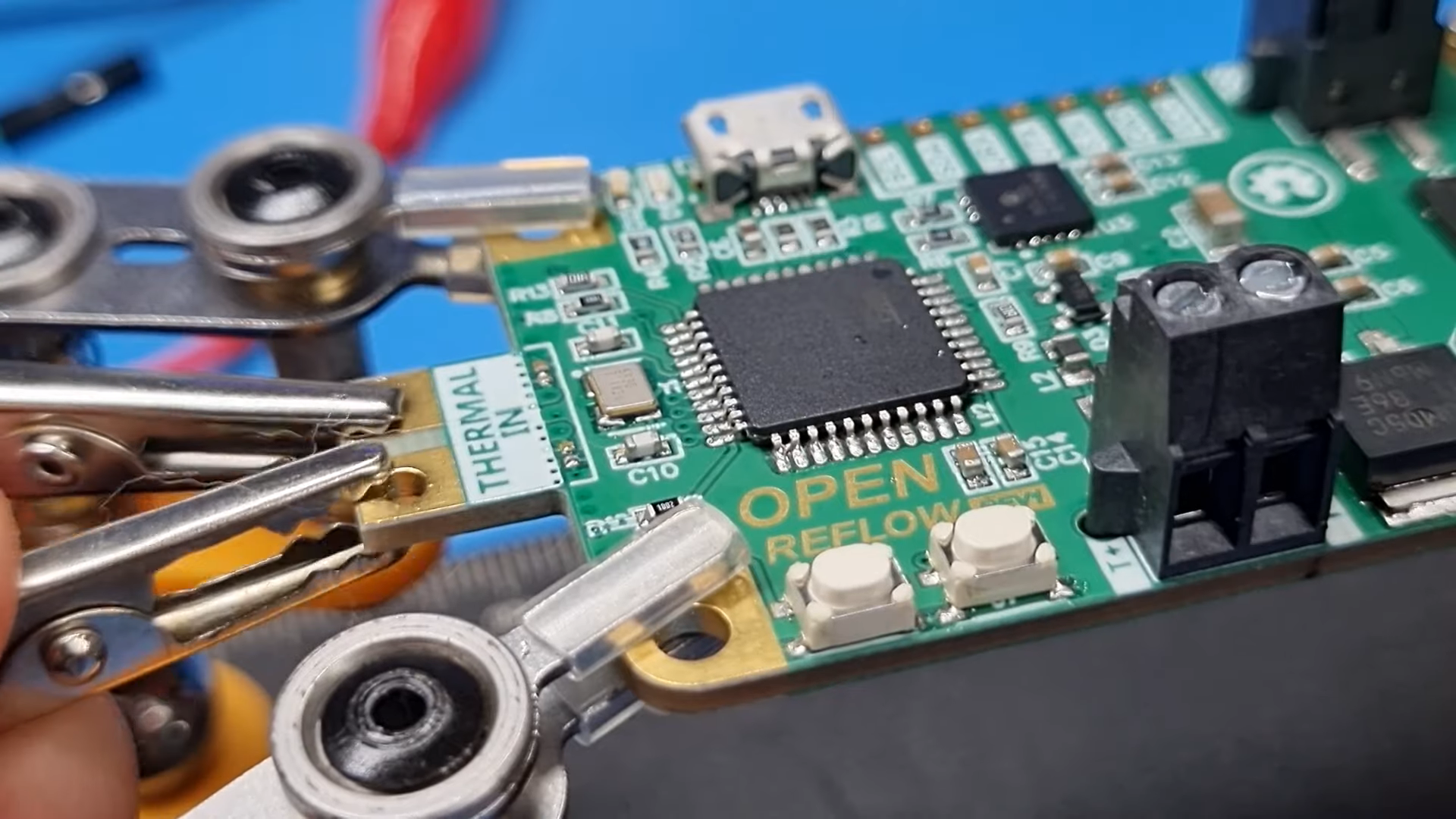

The entire thing is lovely artful, however there’s extra to the tale. The circuit [Carl] selected for his first self-soldering board is in fact a reflow controller. So as soon as the primary board was once manually reflowed with a bench provide, it was once used to regulate the reflow procedure for the remainder of the forums within the batch, or any board with a integrated heating part. We think there might be some obstacles at the measurement of the self-soldering board, regardless that.

We actually like this concept, and we’re having a look ahead to seeing extra from [Carl] in this.

Thank you for the end, [Tobias].